The laser chiller is a cooling device for cooling the generator of laser equipment by water circulation. It can control the temperature of the laser generator and maintain the normal operation of the laser generator for a long time. It is an indispensable and important part of the operation of laser equipment.

The working principle of the laser chiller is to inject a certain amount of water into the chassis, the cooling system cools the water, and then circulates the cooling water to the laser equipment through the coolant pump to achieve the purpose of cooling. Among them, the laser cooling circulation pump plays an important role as the heart of the system, and its main functions are:

1. Promoting the circulation of cooling fluid to realize that excessively high operating temperature of the laser tube will cause irreversible damage and weaken the laser output power. The service life of the laser tube will also be greatly shortened.

2. Provide large and stable flow and head to maintain the performance of the chiller. The water circulation is unstable or the head is too small, which will easily cause poor heat dissipation of the laser chiller module and Q head, and easily cause dirty blockage, which directly affects the performance of the laser chiller. and service life.

Static sealing design, imported Japanese PPE, strict testing, no leakage

forever

Adopting high efficiency brushless motor, low power, low temperature rise, long working life

Laser Chiller Pump Series by TOPSFLO

Voltage 24V

Max Flow 35L/min

Max Water Head 21M

Voltage 12V 24V

Max Flow 20L 24L/min

Max Water Head 8M 11M

Voltage 12V 24V

Max Flow 16L 20L/min

Max Water Head 8M 11M

1.More energy-saving and more efficient! TOPSFLO assists chillers to achieve rapid cooling

2.How to select the water flow rate of laser chillers pump ?

TOPSFLO Helps Chillers Achieve Faster Cooling with Greater Energy Efficiency

As industrial production continues to advance, machines have become integral to modern operations. To ensure optimal performance and maintain product quality, cooling systems—especially chillers—have become an essential part of the process.

What Is a Chiller?

A chiller (also known as a freezer, refrigeration unit, ice machine, or cooling unit) is a type of cooling equipment designed to deliver constant temperature, flow, and pressure for various applications. It works by circulating coolant (usually water or a refrigerant) through the equipment that needs to be cooled, removing heat and returning the coolant to a tank in a continuous loop.

Chillers are widely used across:

• Industrial production

• Electronics and semiconductor cooling

• Medical and pharmaceutical processes

• Food processing

• Laboratory equipment

• 5G base stations

• Energy storage systems and data centers

Their ability to automatically adjust temperature, operate with minimal water consumption, and support long-term use makes them ideal for achieving rapid, stable, and energy-efficient cooling.

The Core Component: Chiller Circulation Pump

At the heart of every chiller lies the circulation pump, which transports coolant through the system. To enhance the overall performance of a refrigeration system, the circulation pump must deliver:

• Maximum efficiency

• Stable high flow rate

• Low energy consumption

• Minimal heat generation

Meeting these demands is crucial to the next generation of high-performance cooling systems.

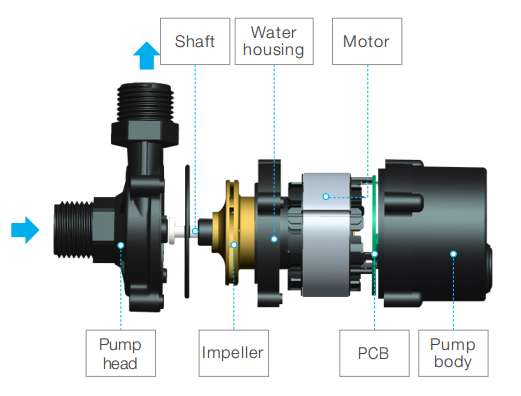

TOPSFLO’s High-Efficiency Chiller Water Pump – TL-C01

TOPSFLO identified these market needs early and launched the TL-C01 chiller water pump, designed to meet the high standards of modern cooling systems.

Backed by a team with over 20 years of experience in micro-pump engineering, TOPSFLO ensures exceptional product performance through:

• Rigorous pre-development evaluations (performance, temperature rise, safety)

• Use of top-tier international electronic components

• Optimized motor and circuit design for minimal heat output

• Enlarged heat dissipation area for superior thermal resistance

• Precision-engineered structure for maximum output at a given power level

As a result, TL-C01 delivers higher flow and efficiency while producing less heat, ensuring it supports rather than interferes with the cooling process.

Performance Benchmark: TL-C01 vs. Market Alternatives

TOPSFLO’s R&D team conducted comparative testing between TL-C01 and other leading 50W pumps in the market. Results showed:

• TL-C01-C delivers a stable flow of 24L/min

• Comparable pumps achieved a maximum of only 18L/min

• TL-C01 chiller water pump is 30% more efficient, delivering greater performance at the same power level

This performance boost translates to faster cooling, lower operational costs, and higher system reliability for end users.

Manufacturing Excellence & Quality Assurance

To ensure mass production quality, TOPSFLO operates over 100 sets of internationally advanced automated production equipment. This enables:

• High production efficiency

• Cost savings for OEMs

• Exceptional batch consistency and reliability

Customers can trust that every pump they receive meets stringent quality and performance standards.

Driven by Innovation, Built for Reliability

TOPSFLO continues to lead the way in precision fluid handling solutions, with a strong portfolio of independent patents and innovative designs. For over two decades, the company has been committed to addressing evolving market demands in cooling systems.

Looking ahead, TOPSFLO will continue to invest in R&D, delivering even more efficient, intelligent, and sustainable pump solutions to customers worldwide.

📩 Interested in improving your chiller system’s performance?

Contact us today for samples and technical consultation: info@topsflo.com

In the selection method of the laser chiller, the water flow and head of the chiller will directly affect the stable operation of the laser chiller in the future.

1) The flow rate of the chiller water pump is too small:

The direct effect of too small flow rate of the water pump is that the heat cannot be quickly taken out from the cooled equipment, causing the temperature of the cooled equipment to rise. And because the cooling water flow rate is not fast enough, the temperature difference between the inlet and outlet becomes larger, so the surface temperature difference of the temperature-controlled equipment is relatively large.

2) The chiller water pump flow rate is too large:

The large flow rate of the water pump makes the cooling effect of the chiller good and the cooling capacity large, which can meet the cooling requirements. However, an excessively large cooling water circulation pump will inevitably increase the equipment cost of the industrial chiller, and the operating cost such as electricity will also increase. The high cooling water flow and pressure will also increase the resistance of the water flow pipe, which will cause unnecessary energy consumption, reduce the service life of the cooling water circulating pump, and may cause many other failure

Recommend you also directly send and email to info@topsflo.com to get our fastest response.